RA Naxaas Bir ah

Foorno Naxaas ah oo Duuban

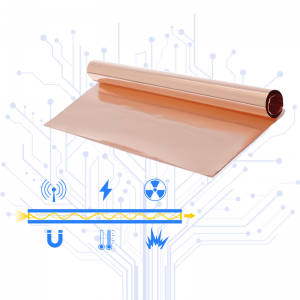

Walxaha birta ah ee ugu badan ee naxaasta ah waxaa loo yaqaan naxaas saafi ah. Waxaa sidoo kale loo yaqaan sidacasaan naxaas sababtoo ah dusha sare muuqataMidab casaan-guduud ah. Naxaasku wuxuu leeyahay dabacsanaan iyo dabacsanaan heer sare ah. Waxa kale oo uu leeyahay koronto iyo kuleyl aad u fiican. Foornada naxaasta ah ee ay soo saartoBIRTA CIVEN ma aha oo kaliya inuu leeyahay daahirnimo sare iyo astaamo nadiifnimo oo hooseeya, laakiin sidoo kale wuxuu leeyahaysiman Dhammaystirka dusha sare, qaabka xaashida fidsan iyo isku-midnimo aad u wanaagsan. Waxay ku habboon yihiin in loo isticmaalo sidii walxaha gaashaanka korontada, kulaylka iyo elektaroonigga. Foornada naxaasta ah ee la duubay laga bilaaboBIRTA CIVEN sidoo kale waa mid aad loo farsamayn karo oo si fudud loo qaabayn karo loona laminate karo. Sababo la xiriira qaab-dhismeedka wareegsan.qaab-dhismeed Foornada naxaasta ah ee la duubay, xaaladda jilicsan iyo tan adag waxaa xakamayn kara habka daadinta, taasoo ka dhigaysa mid ku habboon noocyo badan oo kala duwan codsiyada.CIVEN METAL waxay sidoo kale soo saari kartaa foils naxaas ah. dhumuc iyo ballac kala duwan iyadoo loo eegayo shuruudaha macaamiisha, sidaas darteedna yaraynta kharashyada wax soo saarka iyo hagaajinta hufnaanta farsamaynta.

| Qalabka Saldhigga | C11000 Naxaas, Cu > 99.90% |

| Kala duwanaanshaha dhumucda | 0.01mm-0.15mm (0.0004 inji ~ 0.006 inji) |

| Kala Duwanaanshaha Ballaca | 4mm-400mm (0.16inch ~ 16inch) |

| Dabeecad | Adag, Badh Adag, Jilicsan |

| Codsiga | Transformer, Copper Flexible Connector, CCL, FCCL, PCB, Film Geothermal, Dhismaha, Qurxinta iwm. |

| GB | MAYA DAAQADDA | CABBIRKA (mm) | ||||

| (ISO) | (ASMT) | (JIS) | (BIS) | (DIN) | ||

| T2 | Cu-ETP | C11000 | C1100 | C101 | R-Cu57 | Dhumucda: 0.01-0.15/Ballaca ugu badan: 400 |

| TU2 | Cu-OF | C10200 | C1020 | Cu-OFC | OF-Cu | |

Sifooyinka Farsamada

| Dabeecad | JIS Temper | Xoogga Laabista Rm/N/mm 2 | Kordhinta A50/% | Adkaanta HV |

| M | O | 220~275 | ≥ 15 | 40~60 |

| Y2 | 1/4H | 240~300 | ≥ 9 | 55~85 |

| Y | H | 330-450 | - | 80~150 |

Fiiro gaar ah: Waxaan ku siin karnaa alaab leh hanti kale iyadoo loo eegayo shuruudaha macaamiisha.

Sifooyinka Jirka

| Cufnaanta | 8.9g/cm3 |

| Koronto laydh (20°C) | ugu yaraan 90% IACS si loo yareeyo heerkulkaugu yaraan 80% IACS si loo beddelo heerkulka |

| Qaboojinta kulaylka (20°C) | 390W/(m°C) |

| Modulus-ka dabacsan | 118000N/m |

| Heerkulka jilcinta | ≥380°C |

Cabbirrada iyo Dulqaadka (mm)

| Dhumucda | Dulqaadka Dhumucda | Ballaca | Dulqaadka Ballaca |

| 0.01~0.015 | ± 0.002 | 4~250 | ± 0.1 |

| > 0.018~0.10 | ± 0.003 | 4~400 | |

| > 0.10~0.15 | ± 0.005 | 4~400 |

Tilmaamaha la heli karo (mm)

| Dhumucda | Ballaca | Dabeecad |

| 0.01~0.015 | 4~250 | O,H |

| > 0.018~0.10 | 4~400 | O,H |

| > 0.10~0.15 | 4~400 | O,1/2H,H |

Heerka Xamuulka (Ugu Dambeeyey)

| Qowmiyadaha | Lambarka Caadiga ah | Magaca Caadiga ah |

| Shiinaha | GB/T2059--2000 | Heerka Qaranka Shiinaha |

| Jabaan | JIS H3100:2000 | WARQADAHA, SAXAARADDA IYO XARIIRADA NAAXDA IYO NAAXDA |

| Mareykanka | ASTM B36/B 36M -01 | QEEXIDDA CAADIGA AH EE NAAXADDA, SAXAARADDA, XAASHIDA, XARIIQDA IYO BAR LA DUUBAY |

| Jarmalka | DIN-EN 1652:1997 | SAXAANKA, XAASHIDA, XARIIQDA IYO GOOBAAMADA EE Ujeeddooyinka Guud |

| DIN-EN 1758: 1997 | XADHIGYADA QALABKA NAAXDA IYO NAAXDA EE LAGA SAMEEYAY LEADRAMES | |

| Nus-dhammaadka | NIMIGA G4-0302 | QEEXIDDA Agabka Leadframe-ka Wareega Isku-dhafan ee loo isticmaalo Soo-saarka Leadframes-ka Shaabadaysan |

![[RTF] Foornada Naxaasta ah ee ED ee Dib Loogu Daweeyay](https://cdn.globalso.com/civen-inc/RTF-Reverse-Treated-ED-Copper-Foil-300x300.png)